Courtney & Nye stands as one of the trusted names in this field, furnishing perfection-finagled heat exchangers and specialized moxie to diligence worldwide. This blog explores the part, significance, and value of professional heat exchanger suppliers, while pressing the crucial factors diligence should consider when opting the right mate for their thermal operation requirements.

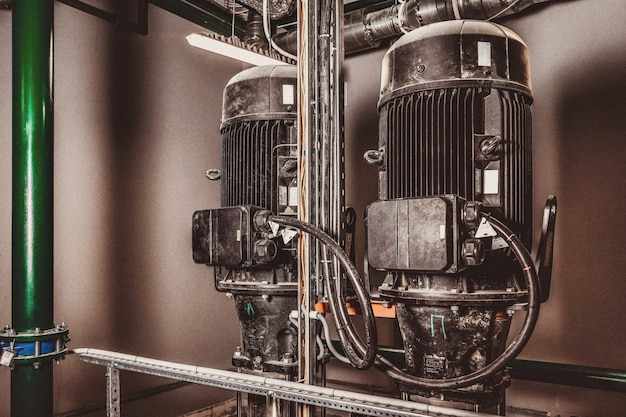

The part of Heat Exchanger Suppliers

Heat exchanger suppliers play a central part in connecting artificial demand with advanced engineering results. Their moxie extends beyond product delivery — they design, manufacture, and support systems that insure effective heat transfer in demanding surroundings.

1. Design and Engineering Expertise

Suppliers are responsible for developing heat exchangers that meet specific functional requirements, similar as fluid type, temperature range, pressure situations, and space constraints. By using thermodynamic principles and advanced accoutrements, suppliers insure that each design offers high performance, trustability, and energy effectiveness.

2. Customization and Rigidity

Every assiduity has unique conditions. Heat exchanger suppliers offer customized results — whether shell and tube, plate-fin, brazed plate, or air-cooled designs — to match precise process conditions. Customization ensures maximum effectiveness, minimum conservation, and long-term continuity.

3. Quality Assurance and Testing

Reliable suppliers follow strict quality norms, including performance testing, pressure checks, and material verification, icing that every unit meets assiduity regulations and safety norms. This commitment guarantees thickness and responsibility in critical artificial operations.

4. Specialized Support and After-Deals Service

Professional suppliers give installation backing, troubleshooting, and conservation support to enhance functional effectiveness. Ongoing service ensures that heat exchangers continue to perform optimally throughout their life cycle.

Courtney & Nye integrates these essential services into its operations, icing diligence admit complete thermal results — not just outfit.

significance of Choosing the Right Heat Exchanger Supplier

opting the right supplier has a direct impact on product effectiveness, functional costs, and long-term sustainability.

1. effectiveness and Performance

High-quality heat exchangers insure maximum thermal transfer effectiveness, reducing energy waste and perfecting system performance. Suppliers who use advanced design tools and accoutrements deliver units that maintain performance under extreme operating conditions.

2. trustability and continuity

Artificial operations depend on outfit that performs constantly. The right supplier ensures robust construction, erosion resistance, and long service life — crucial factors that reduce time-out and conservation costs.

3. Compliance with Industry norms

Trusted suppliers cleave to transnational norms and instruments, icing safety, environmental compliance, and harmonious product quality. This adherence enhances system trustability and functional confidence.

4. Specialized Knowledge and Support

A knowledgeable supplier offers expert discussion, helping diligence elect the most effective heat exchanger type for their operation. Guidance during design, installation, and conservation phases improves performance and minimizes expensive crimes.

5. Innovation and Technology Integration

Top suppliers invest in exploration and development, incorporating inventions similar as advanced blends, compact designs, and digital monitoring results. This ensures their products remain at the van of thermal technology.

Courtney & Nye exemplifies these attributes, offering innovative, durable, and effective thermal systems designed for long-term artificial success.

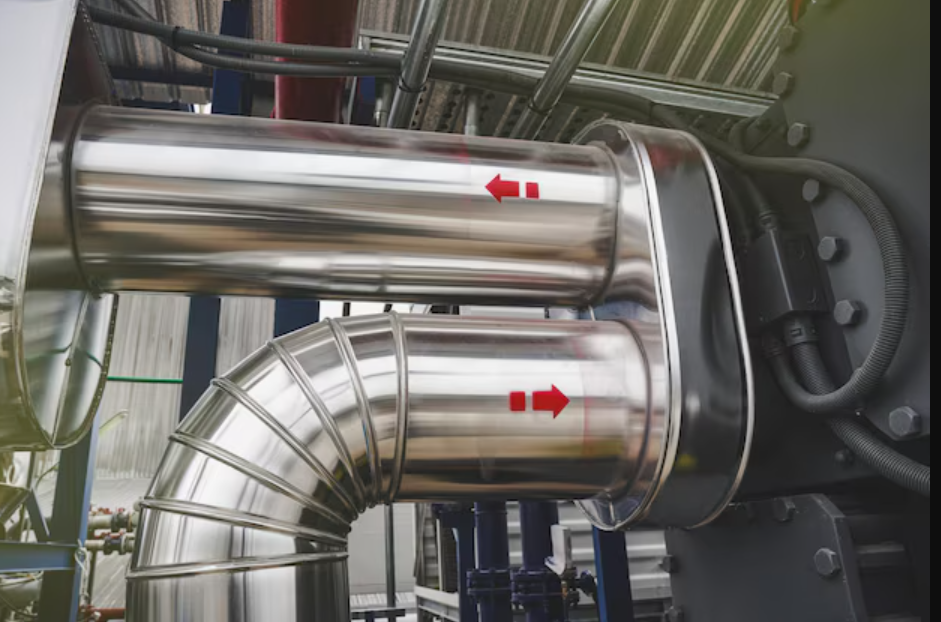

Types of Heat Exchangers Supplied

Professional suppliers offer a wide range of heat exchangers to suit different functional requirements and process conditions. Each type provides distinct advantages grounded on the operation.

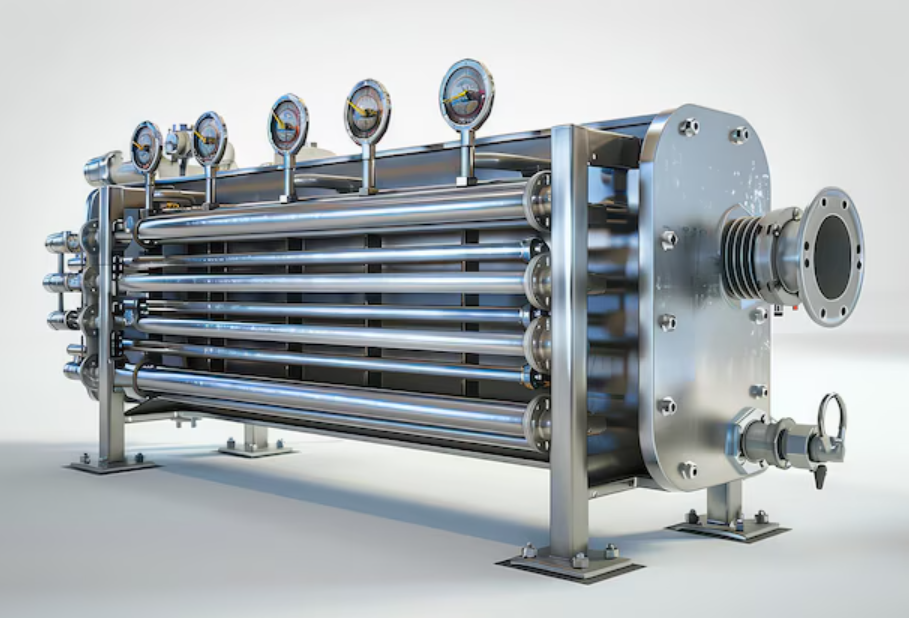

1. Shell and Tube Heat Exchangers

Generally used in power generation, chemical processing, and oil painting refining, these exchangers feature tubes enclosed in a spherical shell. They're ideal for high-pressure and high-temperature operations due to their robust construction and rigidity.

2. Plate Heat Exchangers

These use thin essence plates to separate fluids and increase face area for heat transfer. Compact and effective, plate heat exchangers are extensively used in HVAC systems, refrigeration, and food processing diligence.

3. Air-Cooled Heat Exchangers

Designed for surroundings where water is limited, air-cooled exchangers use ambient air as the cooling medium. They're ideal for remote installations and energy-effective cooling operations.

4. Brazed Plate Heat Exchangers

These compact units are suitable for refrigeration, heating, and artificial cooling processes. Brazed construction eliminates gaskets, icing continuity and leak-free operation.

5. Plate Fin Heat Exchangers

Used in aerospace, cryogenic, and chemical operations, these exchangers handle multiple fluids contemporaneously with high thermal effectiveness in a featherlight, compact form.

Each of these heat exchangers plays a vital part in artificial effectiveness, and suppliers like Courtney & Nye insure their vacuity in customized forms to meet specific functional demands.

Factors to Consider When opting a Supplier

Choosing the right heat exchanger supplier requires careful consideration of multiple factors to insure long-term trustability and performance.

1. Experience and Assiduity Knowledge

A supplier’s experience in handling complex systems indicates their capability to meet specific artificial challenges. Courtney & Nye’s expansive experience across diligence ensures a deep understanding of operation conditions.

2. Material Quality and Manufacturing norms

Accoutrements determine the continuity and effectiveness of a heat exchanger. Suppliers that use erosion-resistant blends and advanced manufacturing ways insure trustability and life under grueling operating conditions.

3. Customization Capability

Diligence frequently need acclimatized results for unique process conditions. Suppliers that offer design inflexibility give better effectiveness and system integration.

4. Specialized Support and conservation Services

nonstop specialized support helps sustain outfit effectiveness and reduces time-out. Reliable suppliers give examination, form, and relief services as part of their immolation.

5. Cost effectiveness and Lifecycle Value

While original cost matters, long-term performance and conservation conditions determine overall value. estimable suppliers balance affordability with continuity, furnishing cost-effective thermal results.

Courtney & Nye combines these critical rudiments, icing diligence admit dependable, effective, and long-lasting heat exchangers that meet their specific functional requirements.

donation to Sustainability and Energy effectiveness

ultramodern heat exchanger suppliers play a crucial part in advancing sustainability. By designing effective heat transfer systems, they help diligence reduce energy consumption, minimize waste, and lower carbon emigrations.

Energy recovery through heat exchangers reduces energy use and supports renewable and energy-effective technologies. Sustainable accoutrements and designs also contribute to reduced environmental impact while maintaining high performance.

Courtney & Nye integrates sustainability principles into its engineering practices, icing every system delivers not only effectiveness but also environmental responsibility.

The Future of Heat Exchanger Supply

As diligence evolve, toast exchanger suppliers are embracing digital technologies, robotization, and advanced accoutrements to meet unborn challenges. Smart covering systems, prophetic conservation, and featherlight, high-effectiveness accoutrements are shaping the coming generation of thermal operation outfit.

Suppliers fastening on invention, customization, and sustainability will continue to play a vital part in global artificial growth. Courtney & Nye remains at the van of this elaboration, furnishing slice-edge results that enhance functional performance and energy effectiveness.

Conclusion

Heat exchanger suppliers are vital partners in the industrial ecosystem, ensuring that thermal processes operate with maximum effectiveness, reliability, and sustainability. Their expertise in design, manufacturing, and technical support allows industries to maintain stable production, reduce energy consumption, and extend equipment lifespan. Among their advanced offerings, the SSCF heat exchanger stands out for its superior thermal efficiency, robust construction, and adaptability across diverse industrial applications.

From opting the right accoutrements to furnishing customized results and after-deals service, professional suppliers like Courtney & Nye insure that each heat exchanger is optimized for performance and life. By fastening on invention, perfection engineering, and sustainable practices, they continue to drive advancements in thermal operation across diligence.

In an period where energy effectiveness and functional excellence define artificial success, the donation of professed heat exchanger suppliers remains necessary. Through quality, moxie, and invention, they help diligence achieve long-term performance, trustability, and environmental responsibility.

Write a comment ...