Vacuum technology plays a pivotal part in ultramodern artificial operations, furnishing essential support for processes similar as chemical product, wastewater treatment, power generation, and material running. Nash vacuum pumps are finagled to deliver dependable, effective, and durable vacuum results across a wide range of operations. Courtney & Nye emphasizes the significance of these pumps in icing functional stability, energy effectiveness, and process trustability in diligence that demand harmonious vacuum performance.

What Are Nash Vacuum Pumps?

Description and Core Function

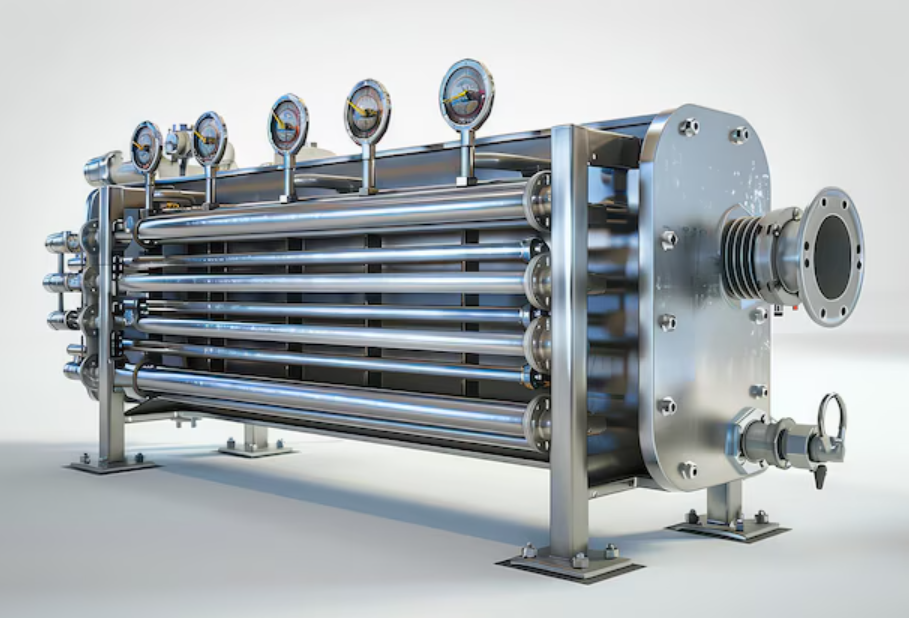

Nash vacuum pumps are mechanical bias designed to remove air or gas motes from a sealed volume, creating a vacuum. This partial vacuum is essential for operations that bear controlled pressure conditions, suction, or degassing. These pumps are largely protean, able of handling feasts, vapors, and condensable fluids while maintaining stable vacuum situations.

Working Principle

The principle of operation depends on the specific pump type. Utmost Nash vacuum pumps operate using a liquid ring or rotary medium:

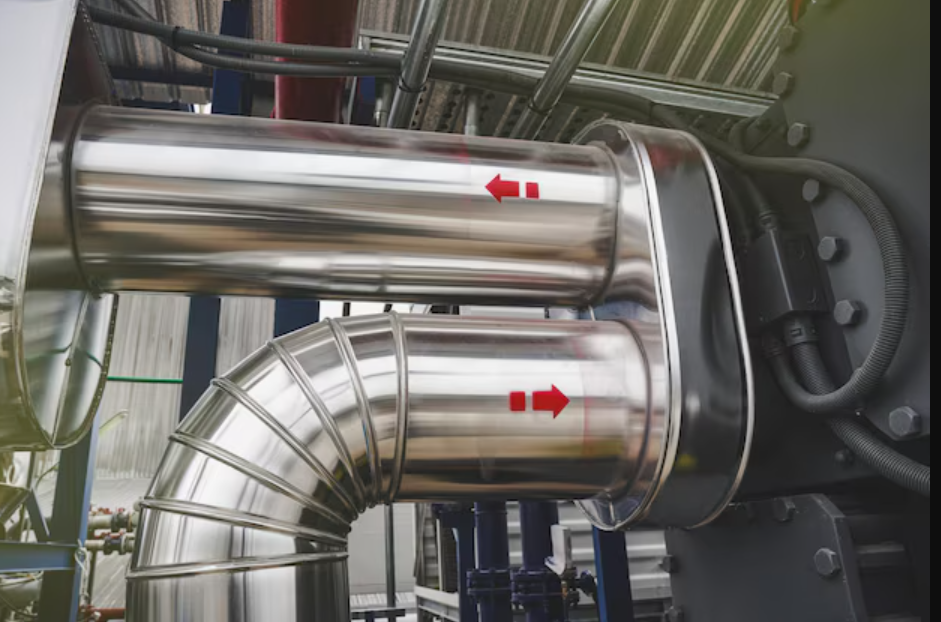

Liquid Ring Pumps: A rotating impeller inside a spherical covering forms a liquid seal that compresses and moves gas out of the system.

Rotary Designs: Use mechanical relegation to produce a vacuum.

The pump removes air or gas continuously, maintaining a low-pressure terrain essential for colorful artificial operations.

Types of Nash Vacuum Pumps

Liquid Ring Vacuum Pumps

Use a sealing liquid to form a ring inside the covering.

Gas enters depressions between impeller blades and the liquid ring, compressing the gas and expelling it through the outlet.

Largely effective in handling condensable vapors and wet feasts, ideal for chemical processing, wastewater treatment, and other demanding operations.

Rotary Vacuum Pumps

Mechanically displace air or gas from the system.

Compact, effective, and suitable for operations taking precise vacuum control.

Frequently used in laboratory surroundings, packaging systems, and light artificial operations.

Claw and Screw Pumps

Use claw or screw mechanisms to induce vacuum.

Designed for dry operation and can handle large volumes of gas without lubrication.

Suitable for diligence that bear impurity-free vacuum, similar as medicinals and food processing.

Industrial Applications of Nash Vacuum Pumps

Chemical and Petrochemical Processing

Essential for distillation, solvent recovery, degassing, and filtration processes.

Give stable pressure control, perfecting process effectiveness, product quality, and functional safety.

Power Generation

Used for condenser evacuation, turbine cooling, and supplementary boiler systems.

Maintain harmonious vacuum situations under shifting cargo conditions, icing dependable energy product and reducing functional stress on outfit.

Wastewater Treatment

Integral for sludge dewatering, vacuum filtration, and aeration.

Liquid ring vacuum pumps handle vapor-laden air, icing effective operation in these surroundings.

Food and Beverage Production

Used in food packaging, vacuum drying, snap-drying, and other temperature-sensitive processes.

Give aseptic, dependable performance, supporting product preservation and harmonious quality.

Pharmaceutical and Laboratory Applications

Precise vacuum control is pivotal for drying, filtration, and logical processes.

Offer low vibration, minimum noise, and stable vacuum situations, supporting high-perfection operations and nonsupervisory compliance.

Advantages of Nash Vacuum Pumps

Running of Vapors and Liquids

Liquid ring vacuum pumps can tolerate small quantities of liquid or condensable vapor in the gas sluice without damage.

Protean for artificial processes where humidity or condensation is present.

Nonstop and Stable Vacuum

Ensures smooth, palpitation-free operation.

Stable vacuum situations are essential for distillation, degassing, and vacuum packaging.

Energy Efficiency

Minimize energy consumption while maintaining high vacuum performance.

Optimized mechanical design and low disunion reduce functional costs.

Continuity and Low Conservation

Constructed from high-quality accoutrements with many moving corridor.

Routine examinations and relief of wear and tear factors maintain performance over time.

Inflexibility Across Operations

Handle colorful feasts, vapors, and process conditions.

Adaptable to wet and dry surroundings, allowing harmonious performance.

Engineering Considerations for System Integration

Pump Sizing and Flow Conditions

Understanding the asked vacuum position, inflow rate, and system volume is essential.

Correct sizing ensures optimal performance, prevents overfilling, and maximizes energy effectiveness.

Fluid Comity

Material selection must match the chemical and thermal parcels of the fluids.

Proper construction prevents erosion, impurity, and unseasonable failure of the pump.

Installation and Functional Terrain

Conditions like ventilation, temperature, and vibration insulation impact pump effectiveness and life.

Proper alignment and support insure stable operation and minimize mechanical stress.

Monitoring and Control Systems

Integration with detectors and automated controls allows drivers to cover vacuum situations, inflow rates, and temperature in real-time.

Prophetic conservation and automated adaptations enhance system trustability and functional effectiveness.

Conservation and Performance Optimization

Routine Examinations

Regular checks for wear and tear, liquid situations, unusual noise, or vibration maintain harmonious vacuum performance and prevent unanticipated time-out.

Drawing and Fouling Prevention

For liquid ring pumps, maintaining the quality of the sealing liquid is essential.

Periodic cleaning and relief help scaling, erosion, and performance declination.

Digital Monitoring

Incorporating detectors and digital controls allows real-time monitoring, prophetic conservation, and process optimization.

Icing long-term effectiveness and trustability.

Unborn Trends in Vacuum Pump Technology

Energy-Effective Designs

Reducing energy consumption while maintaining high vacuum performance.

Bettered impeller design, optimized motor effectiveness, and advanced accoutrements contribute to energy savings.

Smart and Automated Systems

Digital monitoring, prophetic conservation, and automated controls are increasingly integrated into vacuum systems.

Enhance functional trustability and reduce conservation costs.

Expanding Industrial Applications

Advancements in accoutrements and design expand vacuum pump use into:

Renewable energy

High-perfection manufacturing

Advanced chemical processing

Exploration operations

Conclusion

Nash vacuum pumps give a dependable, protean, and energy-effective result for artificial vacuum conditions. Their capability to handle wet and dry feasts, maintain stable vacuum situations, and operate under demanding conditions makes them ideal for:

Chemical processing

Power generation

Wastewater treatment

Food and libation product

Pharmaceutical operations

Courtney & Nye highlights the significance of proper design, material selection, and routine conservation to ensure harmonious performance. With their continuity, energy effectiveness, and rigidity, Nash vacuum pumps continue to be a foundation of ultramodern artificial vacuum technology, trusted by leading heat exchanger suppliers.

Write a comment ...