In ultramodern artificial operations, vacuum systems play a critical part in icing the effectiveness, safety, and thickness of processes. From chemical processing and medicinals to power generation and food product, the demand for dependable and energy-effective vacuum results has noway been advanced. Among the available technologies, screw vacuum pumps have surfaced as a largely effective option for nonstop, high-performance vacuum generation. Known for their robust design, low conservation, and capability to handle grueling operations, screw vacuum pumps are extensively espoused across diligence. Courtney & Nye provides perfection-finagled screw vacuum pumps designed to meet rigorous artificial demands while icing optimal performance and life.

Understanding Screw Vacuum Pumps

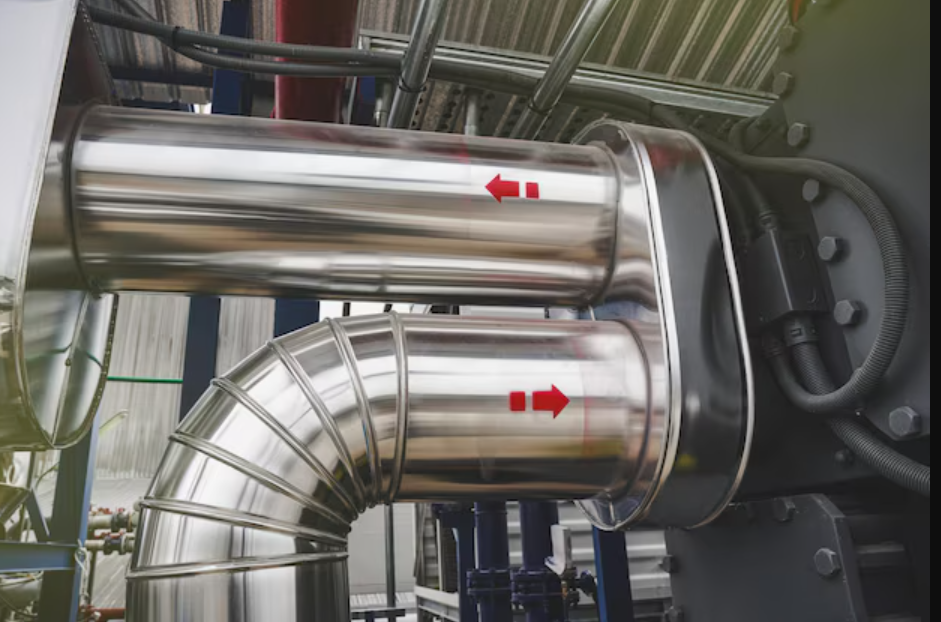

A screw vacuum pump is a type of positive relegation pump that uses two intermeshing rotors to compress and transport gas, creating a vacuum in the process. Unlike conventional pumps that calculate on sliding vanes or liquid rings, screw vacuum pumps achieve nonstop, smooth operation through the accompanied gyration of the screw-shaped rotors.

These pumps are particularly suited for processes taking dependable vacuum situations, low palpitation, and high outturn. Their design allows them to operate under varying gas loads, handle condensable vapors, and maintain effectiveness indeed with shifting operating conditions.

Construction and Design Features

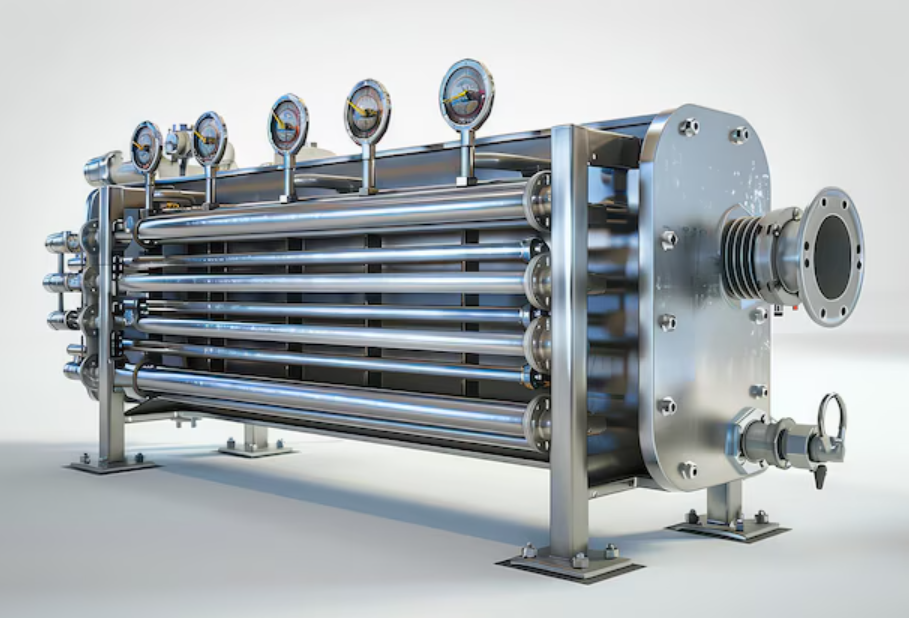

Screw vacuum pumps are designed for continuity, effectiveness, and low conservation. Their crucial factors include:

Rotors

The pump contains two rotors with spiral biographies that rotate in contrary directions. The manly and womanish rotor combination creates sealed depressions that capture and transport gas through the pump.Pump Casing

The covering provides support and alignment for the rotors while maintaining the vacuum seal. Accoutrements are chosen for strength, erosion resistance, and thermal stability.Inlet and Outlet Anchorages

Gas enters the pump through the bay harborage and is compressed as it moves along the rotor depressions. The compressed gas is also expelled through the outlet harborage at advanced pressure.Drive Medium

Electric motors or other power sources drive the rotors, icing precise gyration and nonstop vacuum generation.Sealing and Bearings

Bearings and seals support the rotors while maintaining effectiveness. numerous ultramodern designs are oil painting-free, reducing impurity pitfalls and conservation conditions.

The accompanied rotor design allows for smooth, nonstop operation with minimum palpitation, making screw vacuum pumps ideal for operations that demand steady vacuum situations.

Working Principle of Screw Vacuum Pumps

The working principle of a screw vacuum pump is grounded on the positive relegation of gas. It can be epitomized as follows:

Gas Entry

Process gas enters the pump through the bay harborage and is captured in the depressions formed by the intermeshing rotors.Compression

As the rotors turn, the trapped gas moves along the screw profile toward the discharge end. The volume of the depressions decreases along the rotor length, compressing the gas.Gas Discharge

The compressed gas exits through the outlet harborage at a advanced pressure, completing the vacuum generation process.

This nonstop operation allows screw vacuum pumps to maintain a stable vacuum, with low vibration and minimum palpitation. Unlike other pumps, the absence of sliding seals or liquid rings reduces wear and tear and enhances the pump’s functional lifetime.

Crucial Advantages of Screw Vacuum Pumps

Screw vacuum pumps offer several distinct benefits that make them a favored choice in ultramodern artificial operations:

Nonstop, Palpitation-Free Operation

The intermeshing rotor design ensures smooth, continued vacuum generation, which is critical for sensitive processes.High Effectiveness

Screw vacuum pumps maintain high pumping effectiveness over a wide range of pressures and gas loads, reducing energy consumption.Low Conservation Conditions

With smaller moving corridor and robust construction, screw vacuum pumps bear minimum conservation compared to vane or liquid ring pumps.Capability to Handle Condensable Vapors

These pumps can handle wet feasts and condensable vapors without compromising vacuum performance, reducing the need for fresh vapor traps.Oil Painting-Free Operation Options

numerous screw vacuum pumps are designed for dry operation, barring impurity pitfalls in sensitive operations similar as medicinals and food processing.Durable and Reliable Design

Engineered for long-term performance, screw vacuum pumps are resistant to wear, erosion, and thermal stress, icing harmonious operation in demanding artificial surroundings.Flexible Operation Range

Suitable for a variety of diligence and operations, screw vacuum pumps give adaptable results for different pressure conditions and gas compositions.

Operations of Screw Vacuum Pumps

Screw vacuum pumps are protean and used in multitudinous artificial operations due to their robust design and harmonious performance. Crucial operations include:

Chemical and Petrochemical Diligence

Used in distillation, drying, solvent recovery, and vacuum filtration processes. Their capability to handle vapors and sharp feasts makes them ideal for these operations.Pharmaceutical Manufacturing

Applied in snap-drying, vacuum drying, and sterilization processes where impurity-free vacuum is essential.Food and Beverage Processing

Used for packaging, vacuum cooling, and dehumidification processes, icing product quality and safety.Power Generation

employed in condenser evacuation, boiler degassing, and other processes taking dependable vacuum at varying loads.Plastics and Polymer Product

Supports degassing, extrusion, and vacuum molding operations, maintaining harmonious product quality.Environmental Engineering

Employed in wastewater treatment, vacuum distillation, and gas recovery operations where nonstop operation is critical.Electronics and Semiconductor Manufacturing

Provides stable vacuum conditions necessary for coating, drying, and other sensitive product processes.

The rigidity of screw vacuum pumps allows diligence to optimize their processes, ameliorate energy effectiveness, and reduce functional costs.

Performance Considerations

The performance of screw vacuum pumps depends on several factors:

Rotational Speed and Rotor Design

Determines the inflow rate and vacuum position attainable.Gas Composition

Non-condensable and sharp feasts can affect effectiveness, taking careful material selection.Operating Temperature

Maintaining temperature within design limits prevents rotor distortion and ensures harmonious vacuum.Conservation and Lubrication

Proper lubrication (or oil painting-free operation) ensures smooth operation and extends the pump’s lifetime.

Courtney & Nye designs squinch vacuum pumps with perfection, optimizing these factors to deliver harmonious performance and long-term trustability.

Conservation and Functional Benefits

Screw vacuum pumps are designed for low-conservation operation, but routine checks enhance their effectiveness and continuity:

Monitoring Pressure and Flow

Regular checks insure the pump operates within design parameters.Examination of Bearings and Seals

Prevents unseasonable wear and tear and ensures smooth operation.Drawing Inlet Filters

Protects rotors from impurity and maintains effectiveness.Fluid Quality in Lubricated Pumps

Ensures optimal lubrication and prevents internal erosion.

Proper conservation extends the pump’s functional life and reduces the threat of unplanned time-out, a critical factor in nonstop artificial processes.

Environmental and Energy Effectiveness Benefits

Screw vacuum pumps contribute to energy conservation and environmental responsibility in several ways:

Reduced Energy Consumption

High-effectiveness designs minimize power operation.Impurity-Free Operation

Oil-free models help environmental impurity and reduce waste operation conditions.Lower Noise Situations

Smooth operation reduces noise pollution in artificial surroundings.

These features make screw vacuum pumps a sustainable choice for ultramodern artificial operations, balancing performance, energy effectiveness, and environmental responsibility.

Conclusion

Screw vacuum pumps are an necessary element in ultramodern artificial vacuum systems, offering dependable, energy-effective, and low-conservation results for a wide range of operations. Their robust design, smooth operation, and capability to handle grueling feasts make them ideal for diligence ranging from medicinals and food processing to chemical product and power generation.

Courtney & Nye provides advanced screw vacuum pumps finagled for optimal performance, continuity, and functional effectiveness. With perfection design, high-quality accoutrements, and a focus on invention, these pumps insure harmonious vacuum generation, bettered process effectiveness, and long-term value for artificial operations worldwide.

By opting screw vacuum pumps from trusted suppliers like Courtney & Nye, diligence can achieve superior process control, energy savings, and dependable performance, making them an essential asset in ultramodern artificial systems.

Write a comment ...