Vacuum technology is a vital element of ultramodern artificial processes, enabling effective gas junking, controlled pressure surroundings, and safe operation of critical systems. Among colorful types of nash vacuum pumps, liquid ring vacuum pumps — generally known for their robustness and trustability — stand out for their capability to handle condensable vapors and variable process conditions. Courtney & Nye provides advanced vacuum pump results that combine effectiveness, continuity, and versatility, making them ideal for a wide range of artificial operations.

This blog explores the design, functional principles, advantages, artificial uses, and conservation strategies for Courtney & Nye vacuum pumps, pressing their value in optimizing process performance.

Preface to Liquid Ring Vacuum Pumps

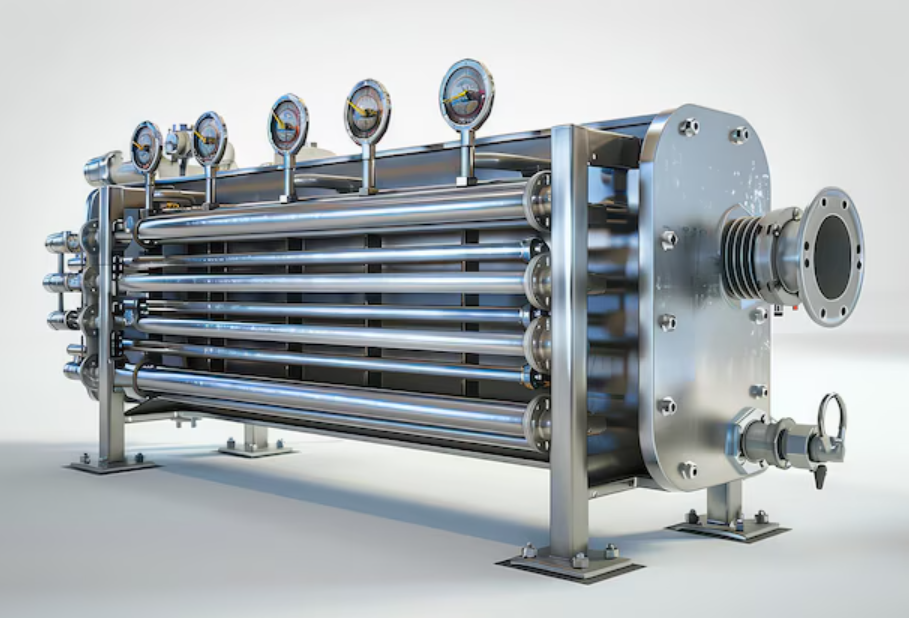

Liquid ring vacuum pumps are a subtype of positive relegation pumps designed to produce a vacuum in a system using a rotating impeller and a sealing liquid. Unlike dry pumps, liquid ring designs can handle humidity, brume, and vapors without compromising effectiveness.

Courtney & Nye vacuum pumps are finagled to deliver harmonious vacuum situations, energy-effective performance, and high trustability, making them suitable for diligence where process integrity and uptime are critical.

Crucial Features of Courtney & Nye Vacuum Pumps

Robust Design

The core of a liquid ring vacuum pump is its rotor and containing assembly, where the liquid ring forms a seal around the rotor blades.

Erected using high-quality accoutrements resistant to erosion, wear, and thermal stress, icing long-term continuity.

Protean Fluid Handling

Handles wet feasts, condensable vapors, and process fluids without threat of damage.

Suitable for chemical, medicinal, and food-processing operations.

Effective Operation

Optimized rotor figure and internal design reduce energy consumption while maintaining stable vacuum situations.

Finagled for smooth, low-vibration operation, reducing noise and mechanical wear and tear.

Simplified Conservation

Designed with conservation in mind.

Accessible comportments, rotors, and seals allow for quick examinations, servicing, and relief, minimizing time-out and functional dislocation.

How Courtney & Nye Vacuum Pumps Work

The operation of a liquid ring vacuum pump is both effective and dependable:

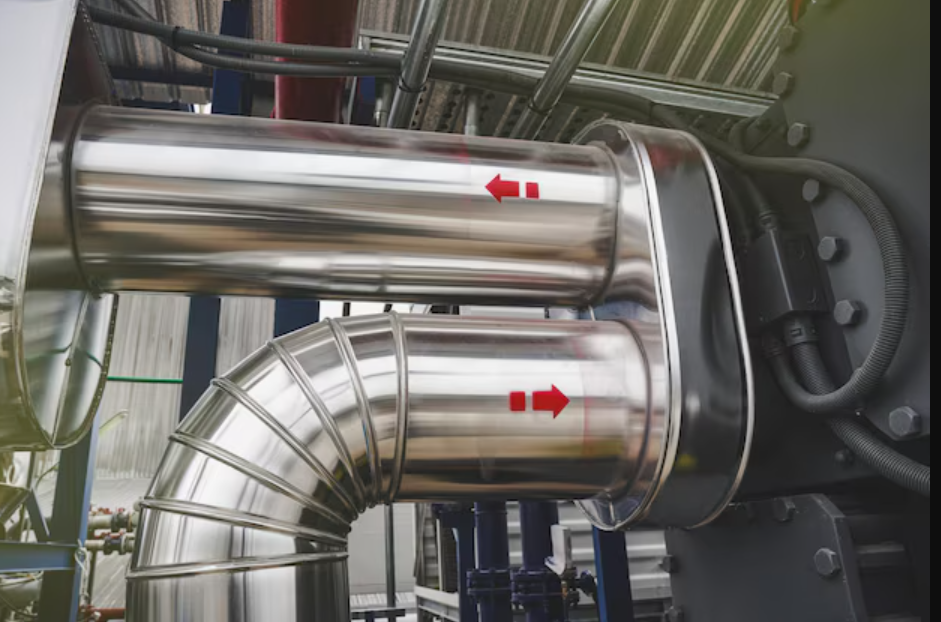

A rotor rotates eccentrically inside the covering filled with a sealing liquid.

Gas enters the suction harborage and is trapped in the depressions formed between the rotor blades and the liquid ring.

As the rotor turns, the trapped gas is compressed against the liquid ring.

The compressed gas is discharged through the outlet, creating a vacuum at the suction point.

This liquid-ring medium ensures the pump can continuously handle vapor-laden or condensable feasts without overheating or losing effectiveness.

Advantages of Courtney & Nye Vacuum Pumps

Handles Condensable Vapors

Numerous artificial processes induce brume or chemical vapors that can damage dry pumps.

Safely handles condensable vapors, ideal for distillation, drying, and solvent recovery operations.

Reliable Nonstop Operation

Minimum moving corridor exposed to gas or vapor.

High trustability under nonstop operation, reducing failure threat in critical systems.

Low Noise and Vibration

Generates lower vibration and noise compared to mechanical or dry vacuum pumps.

Enhanced functional comfort and reduced mechanical stress.

Energy Effective

Optimized internal figure ensures maximum vacuum generation with minimum energy consumption.

Helps diligence reduce functional costs.

Easy Integration

Compatible with chemical reactors, vacuum dryers, packaging ministry, and condensers.

Furnishes inflexibility for artificial integration.

Industrial Applications

Chemical and Petrochemical Processing

Critical for distillation, evaporation, and solvent recovery.

Handles sharp feasts and high temperatures while maintaining harmonious vacuum situations.

Pharmaceutical Industry

Essential for drying, filtration, and sterilization.

Delivers impurity-free operation and precise vacuum control for sensitive processes.

Power Generation

Used in brume condensation, turbine systems, and cooling circles.

Provides stable vacuum situations, helping maintain turbine effectiveness and reduce cavitation.

Food and Beverage Processing

Used for dehumidification, packaging, and sterilization.

Handles wettish or vapor-laden aqueducts, supporting food safety and harmonious quality.

Environmental and Waste Management

Used in wastewater treatment and chemical recovery for effective gas junking and vapor recovery.

Supports nonsupervisory compliance and environmental sustainability.

Conservation and Functional Stylish Practices

Regular Examinations

Check rotor, comportments, seals, and covering for wear, erosion, or leaks.

Easy access allows quick visual checks and precautionary conservation.

Seal Liquid Management

Maintain correct type and position of sealing liquid.

Regular monitoring ensures harmonious vacuum generation and protects against erosion or scale buildup.

Bearing and Drive Conservation

Check for bearing wear, vibration, and lubrication quality.

High-quality comportments and drive systems ensure long life.

Preventative Conservation

Helps prevent unanticipated time-out.

Clear guidance for service intervals ensures long-term functional trustability.

Energy Effectiveness and Environmental Benefits

Contributes to energy-effective operations with stable vacuum situations and minimum electrical consumption.

Handling wet feasts reduces need for fresh cooling or condensate systems, diminishing water usage and environmental impact.

Reduces waste and functional costs, supporting sustainable artificial practices.

Why Choose Courtney & Nye Vacuum Pumps

Key benefits include:

High trustability for nonstop operation in demanding conditions.

Capability to handle condensable and vapor-laden feasts safely.

Energy-effective design to reduce functional costs.

Easy conservation and utility.

Versatility across multiple diligence, including chemical, medicinal, food, and power generation.

Choosing Courtney & Nye ensures efficient, safe, and minimal time-out operations, making them a trusted mate for vacuum technology results.

Conclusion

Vacuum pumps are a cornerstone of modern industrial operations, and liquid ring designs are especially effective for processes involving wet or vapor-laden gases. Courtney & Nye vacuum pumps provide reliable, energy-efficient, and durable solutions for chemical processing, pharmaceuticals, power generation, food and beverage, and environmental systems. Their robust construction, precise engineering, and low maintenance requirements ensure consistent vacuum performance, operational safety, and long-term efficiency, making them a trusted choice among leading heat exchanger suppliers.

Write a comment ...