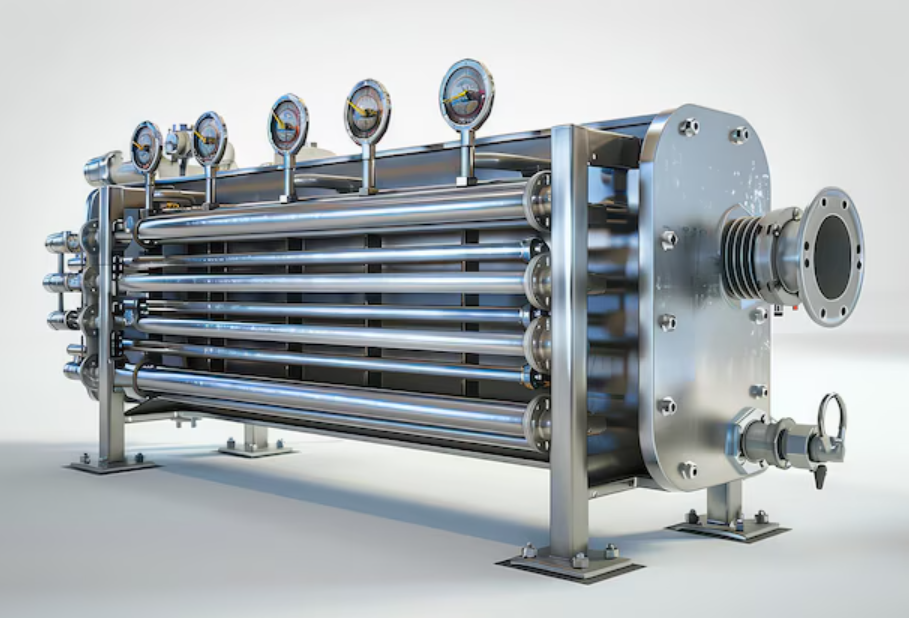

To keep efficiency, quality, and hygiene, the food and beverage sector mostly depends on modern equipment. Vacuum technology is one of the essential parts in this industry since it is very important in several uses including packaging, drying, degassing, and conveying. Leading supplier of vacuum pumps, Elmo Rietschle has gained industry trust from its energy-efficient and high-performance products. Elmo Rietschle vacuum pumps will help food and beverage companies greatly increase output, guarantee product purity, and keep compliance with strict industry standards.

Improved Packaging Solutions for Food

Essential in the food sector, vacuum packaging helps to keep freshness, increase shelf life, and maintain product quality by means of freshness preservation mechanism. By offering stable and dependable vacuum levels that eliminate oxygen from packing, Elmo Rietschle vacuum pumps are absolutely vital in this field. This guarantees food products remain safe and appealing for consumers by preventing microbial development, oxidation, and deterioration.

These vacuum pumps also help automated packing operations be fast and efficient. Maintaining a constant vacuum helps them to lower cycle times, prevent packing mistakes, and cut downtime. For food processing businesses, this yields better general efficiency, reduced running expenses, and increased production.

Enhanced Product Management and Communication

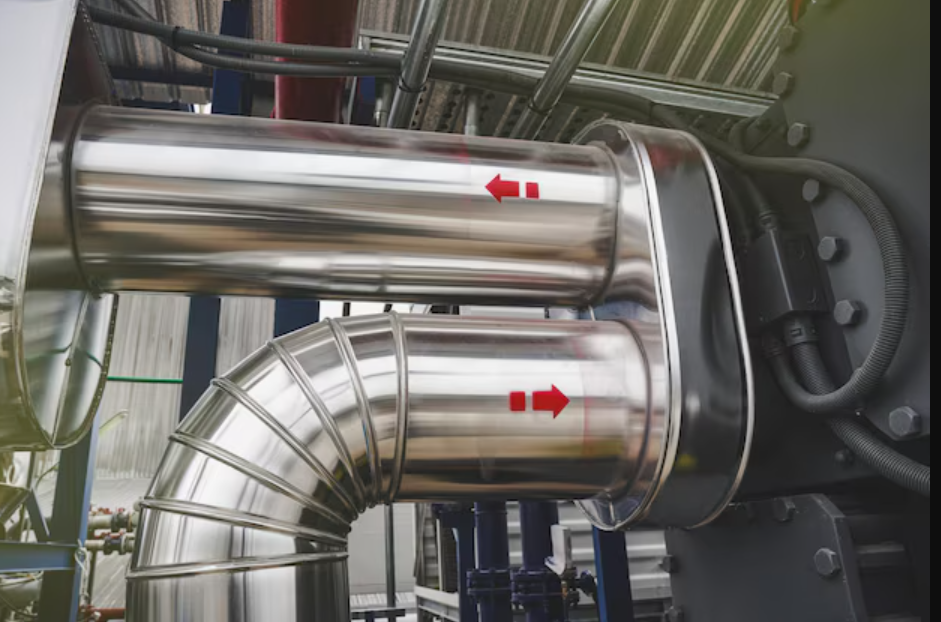

For the delicate handling and shipping of products like grains, coffee beans, sugar, and powdered components, many food and beverage producers depend on vacuum technology. Elmo Rietschle vacuum pumps enable pneumatic conveying systems guaranteeing effective material movement without generating pollution or product degradation.

Using vacuum pumps for conveying helps companies avoid the requirement for mechanical transportation methods, which can involve moving elements that might cause irregularity or damage of products. Vacuum transport is a recommended choice for businesses that give hygiene and product integrity top priority since its non-contact character lowers contamination hazards. Furthermore, Elmo Rietschle's energy-efficient pumps help lower energy usage, therefore enabling a more environmentally friendly and reasonably priced conveying system.

Degassing to Improve Product Quality

Production of many food and beverage products including chocolate, sauces, and beverages depends critically on degassing. To improve texture, appearance, and shelf stability, the process entails getting undesired air or gas bubbles from liquid and semi-liquid items out. Elmo Rietschle vacuum pumps guarantee complete degassing by designing a regulated vacuum environment whereby gases may be effectively removed.

For instance, degassing is necessary in chocolate manufacture to attain a smooth and consistent texture free of air pockets. In the same vein, in beverage production it guarantees constant taste and quality by helping to maintain carbonation levels and by preventing oxidation. Food manufacturers can increase mouthfeel, enhance product appearance, and lower faults by employing Elmo Rietschle vacuum pumps, so raising customer happiness.

Effectful Dehydration and Freeze Drying

In the food sector, freeze drying and dehydration are extensively applied techniques to preserve perishable goods while maintaining their nutritional content, taste, and texture. By lowering ambient pressure and enabling water to be extracted at lower temperatures, vacuum pumps are absolutely vital in many procedures. This helps to retain the food's original qualities and stops heat damage.

Reliable performance in freeze-drying and dehydration uses is what Elmo Rietschle vacuum pumps are meant to deliver. Their capacity to produce deep vacuums guarantees effective moisture removal, therefore producing dried goods of better quality with longer shelf life. These pumps' energy-efficient design also helps producers save running costs and increase sustainability.

Clean and Safe Operation

Strict hygienic and safety rules guide the food and beverage sector to guarantee customer health and avoid contamination. Built to satisfy the strictest hygienic standards, Elmo Rietschle vacuum pumps have clean-running technologies free of oil, therefore reducing the risk of contamination.

Elmo Rietschle's dry-running models remove the need for oil changes, therefore lowering maintenance requirements and the possibility for product contamination unlike conventional oil-lubricated vacuum pumps. These pumps are perfect for uses where cleanliness is a top concern since they are also built of food-grade materials compliant with industry requirements.

Cost Reductions and Energy Efficiency

Energy economy of Elmo Rietschle vacuum pumps is one of its main benefits. Many times consuming large quantities of energy, traditional vacuum pumps raise running expenses. Elmo Rietschle does, however, create its pumps with creative energy-saving technologies that maximize performance while lowering power usage.

Their variable speed technology, for example, helps vacuum pumps to change power output depending on demand, therefore preventing needless energy waste. Food and beverage producers should thus choose this environmentally responsible option since it lowers carbon footprints and resulting in cheaper electricity bills. Elmo Rietschle vacuum pumps are a wise long-term investment since over time the cost savings from better energy efficiency help to increase return on investment.

Reliable Performance with Low Downtime

Reliability is critical in a fast-paced field where downtime may cause major losses. Designed for lifetime and continuous operation, Elmo Rietschle vacuum pumps guarantee that food manufacturing lines stay running without breaks.

Their sophisticated construction reduces wear and tear, therefore lowering the frequency of maintenance and repairs needed. These pumps also include simple control systems that let one monitor and troubleshoot them easily. Food producers can avoid unplanned breakdowns, prolong equipment lifetime, and keep production efficiency by means of this proactive maintenance technique.

Industry Regulatory Compliance

To guarantee food safety and quality, the food and beverage sector has to follow strict legislative criteria. Elmo Rietschle vacuum pumps are made to follow FDA and EU rules as well as other worldwide food safety standards.

Companies that give regulatory compliance first priority choose them because of their low maintenance needs, clean running performance, and ability to operate in controlled environments. Food producers may boldly satisfy hygienic and safety standards by adopting Elmo Rietschle vacuum pumps, therefore lowering their chance of non-compliance fines and recalls.

At last

Offering unparalleled efficiency, dependability, and cost-effectiveness, Elmo Rietschle vacuum pumps have become great allies in the food and beverage sector. From bettering food packaging and product handling to degassing, freeze drying, and general cleanliness, these vacuum pumps provide food producers a complete answer. Companies trying to maximize operations and keep high product quality choose them because of their low maintenance needs, energy-efficient design, and industry standards compliance.

Food and beverage manufacturers can increase output, lower waste, and guarantee the long-term viability of their operations by including Elmo Rietschle vacuum pumps into their manufacturing lines. Investing in innovative vacuum technologies is still very vital as the sector develops towards operational excellence and sustainability.

Write a comment ...